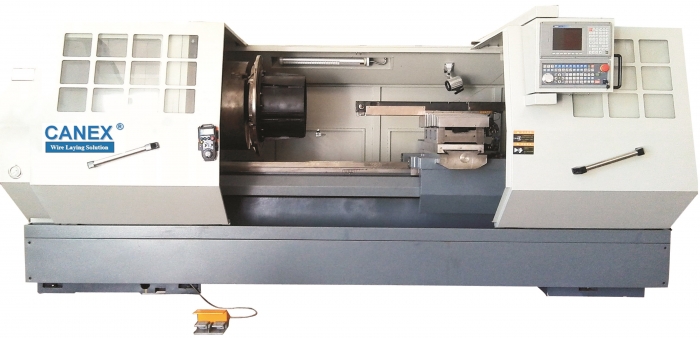

| Name: | Electrofusion Wire Laying Machine |

|---|---|

| Model: | CX-500/1000ZF |

| Weight: | 7400kg |

| Power: | 34KW |

| Dimension: | 5.1x2.3x2.5m |

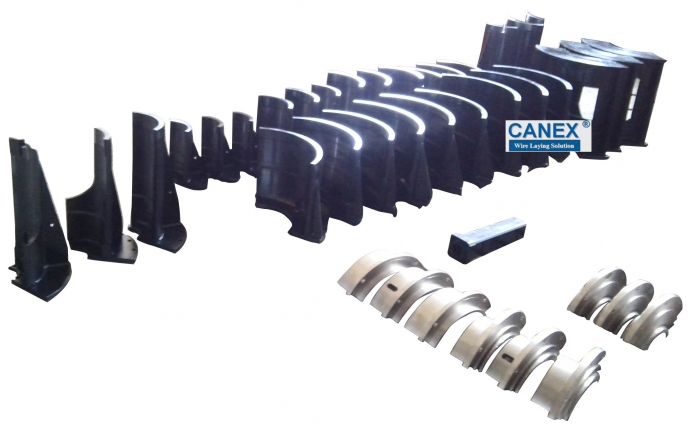

| E/F Coupler: | dn500-1000 |

| E/F Reducer: | dn500-1000 |

| E/F Tee: | dn400-630 |

| E/F Elbow: | dn400-630 |

| Machine cover: | Full closed |

| Safety door: | Manual |

| Fitting made of: | Inject billet or PE segment |

| Protection 1: | Clamping protection |

| Protection 2: | Air intake testing protection |

Allen Hao

Allen Hao

CX-500/1000ZF CNC Electrofusion Wire Laying Machine

Electrofusion fitting produced by CNC Electrofusion wire laying machine.

Benefit

1) High product dimensional accuracy:

The electrofusion pipe fittings produced by the CNC wiring equipment are the inner hole size obtained by turning under room temperature.

The inner hole size of the pipe fittings is stable and high in accuracy, and the ovality can be controlled within ±0.1mm.

2) Stable production quality:

The electrofusion fittings produced by the Electrofusion wiring equipment by CNC machining programs compiled in the equipment system,

and the resistance value of the fittings can be controlled within ±0.02Ω.

3) Convenient adjustment of pipe fitting process:

The inner hole size and parameters of the pipe fitting are controlled by the programmed CNC program. If the inner hole size and wiring parameters of

the pipe fitting need to be changed, the relevant parameters of the pipe fitting can be modified only by modifying the related CNC program.

4) High production efficiency of pipe fittings:

the equipment adopts repeated positioning and processing, which reduces the traditional electrofusion pipe fitting : produce PE coated wire, winding,

core de mould, lifting equipment and other complicated procedures. The pipe fittings can be wired in one clamping on the wiring machine, greatly Improve the production efficiency.

Operating procedures:

1) Clamping: the product is placed in the tooling, the equipment automatically completes pneumatic clamping and fixes the product billet.

2) Rough machining: The equipment automatically turning the inner wall of the pipe fitting according to the compiled CNC program to

make the inner diameter of the pipe fitting reach the specified size.

3) Wiring: The equipment automatically performs wiring processing on the inner wall of the pipe fitting according to the prepared CNC program,

so that the parameters of the heating wire embedded in the inner wall of the pipe fitting meet the requirements of the pipe fitting process design.

The above-mentioned processing steps are completed at one time, and the machine only needs to press the start button and the equipment will make products according to the compiled CNC program.

We provide the terminal pin installing device, fitting welding barcode software, trace barcode software. printer, resistance meter etc...

PE electrofusion wire laying equipment | cnc wire laying machine | coupling wire laying machine | fitting wire laying

| canex international | electrofusion fitting wire laying machine |Pe fitting wire laying | canex machine

tapping saddle lay wire machine