| Name: | E/F Tapping Tee Mould |

|---|---|

| Name: | Electrofusion tapping tee mould |

| Mould Type: | Original processing, Inlay frame mould |

| Follow Standard: | EN1555.3 & EN12201.3 |

| Mould Cavity: | Single or multiple cavities |

| Cavity Material: | P20, 40cr Forge, 718H |

| Design Software: | CAD,ProE,UG etc. |

| Mould Life: | 30,0000-100,0000 cycles |

| Inject Material: | PE,PP-R,PE-RT |

| Mould Texture: | As per sample or Film |

| Runner: | Hot runner, cold runner |

| Surface Treatment: | Nickel or Chrome plating, or QPQ |

| Delivery Time: | 45-60 days |

| Package: | Polywood case |

Allen Hao

Allen Hao

Electrofusion-tapping-tee-mould

E/F Tapping tee/tapping saddle/branch saddle Mould

Professional and experienced design team:

The electrofusion fitting has its special properties.

It is not only a plastic product, but also functions as a connection by applying a certain current and voltage

to both ends of the heating wire implanted on the inner wall of the pipe fitting to melt the plastic through heat.

The design of electrofusion fittings needs to consider: the application field of the product, the geometric size and

strength of the product, the core is the design of the electrofusion welding process,

such as: the diameter of the copper wire, the pitch of the wiring, the current and voltage of the welding, etc.,

in the design for many years We have accumulated relevant parameter data.

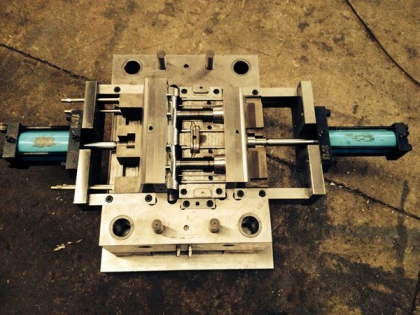

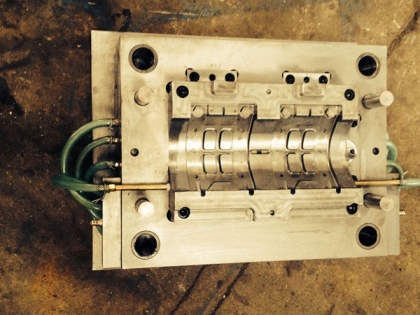

Reasonable water transportation layout:

Reasonable water transportation layout of molds is the key to improving product production efficiency.

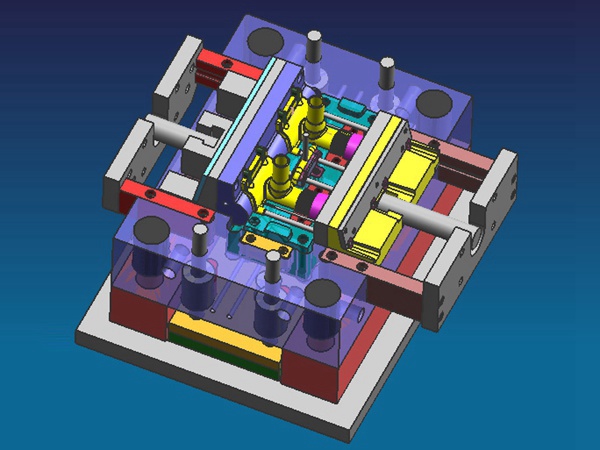

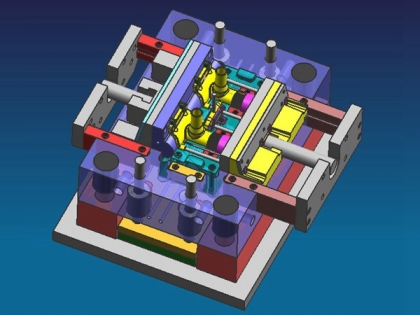

Tapping tee injection mould Fig as follow :